Bipropellant rocket

A bipropellant rocket engine is a rocket engine that uses two propellants (very often liquid propellants) which are kept separately prior to reacting to form a hot gas to be used for propulsion.

In contrast, most solid rockets have single solid propellant, and hybrid rockets use a solid propellant lining the combustion chamber that reacts with an injected fluid. Because liquid bipropellant systems permit precise mixture control, they are often more efficient than solid or hybrid rockets, but are normally more complex and expensive, particularly when turbopumps are used to pump the propellants into the chamber to save weight.

Properties of bipropellant rockets

Bipropellant rocket engines are extremely powerful rockets- they can provide the highest specific impulse (ISP) of all current Earth launchable rocket engines whilst at the same time as providing thrust to weight ratios of 70-100+, and permitting extraordinarily lightweight tankage and vehicle structure.

The highest ISP bipropellant rocket engine in existence is the hydrogen/oxygen fuelled SSME which gives very high performance; but in terms of overall performance the dense-fuelled NK-33 is comparable due to better mass ratios; in spite of lower specific impulse.

Principle of operation

Bipropellant rockets have to introduce the propellants into the chamber at high pressure, mixing them well to give stable and thorough combustion and stop the chamber from melting.

As propellants need to leave the tanks at sufficiently high rate they are stored under pressure, normally as liquids for maximum density. Gaseous storage can be used but is rarely employed as the tanks are inevitably heavy. Liquid propellants are pressurised by a pressurant gas, either an inert one, often helium, or in some cases the vapourised propellant itself is used. Early experiments by Goddard of directly pressurising the fuel with oxidiser vapour led to frequent in-tank explosions, and this is no longer done; although sometimes a common tank is used with flexible membrane or piston to avoid mixing.

The propellants must be introduced into the combustion chamber at high pressure (typically 2 to 20 MPa (20–200 atm) and reasonably high flow (0.1-1000+ liters per second). This is achieved either via high pressure (heavy) tankage, or from lightweight, low pressure tankage through suitable pumps. The pumps used are typically turbopumps, often powered by tapping off 1-2% of the propellants or using a separate system, such as decomposed hydrogen peroxide and powering the pump via a gas turbine. The exhaust from the gas turbine is either dumped over the side, used to cool the nozzle, or placed into the combustion chamber. These turbopumps are the most complex aspect of the bipropellant system. The Space Shuttle Main Engine's turbopumps spin at over 30,000 rpm, delivering 150 lb of liquid hydrogen and 896 lb of liquid oxygen to the engine per second.[1]

Propellants are introduced to the combustion chamber through injectors. Injectors can be as simple as drilled holes with sharp edges which aim jets of liquid propellants to collide with the optimum mixture ratios. However, liquid fuels are not precisely flammable- the liquids must be first turned to gas before combustion can take place. This readily occurs within the engine, but takes longer, uses up volume in the chamber and can cause combustion instabilities. High performance rocket engines such as the Space Shuttle Main Engines take great pains to gasify the propellants before injection into the chamber. This gives more thorough, quicker and much more stable combustion; and permits the combustion chamber to be smaller and hence lighter.

The injectors' job is also to drop the pressure slightly from the propellant line feeds. This decouples the flow through the injectors from the natural variations in chamber pressure that occur during the combustion process. Failure to drop sufficient pressure in the injectors can cause oscillations in pressure in the chamber that can badly damage the engine and cause 'hard-starts' or even self disassembly of the engine during the ignition process.

The high temperature combustion products accelerate along the chamber from the injectors and then pass through the throat; and then expand out the nozzle, pressing on the inside of the nozzle, accelerating and generating an equal and opposite thrust on the rocket.

Cooling

Bipropellant rockets can use any of the standard cooling systems used by rockets. See Rocket engine cooling.

Ignition

Prompt ignition of bipropellant rocket engines at start-up to avoid hard starts is critical, particularly on manned rockets. XCOR Aerospace recommend using a choked igniter (essentially an overengineered mini rocket engine in its own right) with a pressure sensor interlock to detect the presence of a steady ignition source before introducing the propellants into the combustion chamber, together with an oxidiser lead on startup and an oxidiser lag on shutdown to empty the chamber of fuel.[2]

However the presence of these extra interlocks can reduce the reliability of achieving the mission objectives, and simply using a well-tested powerful igniter has been shown to be more effective for unmanned missions, at the cost of increased risk of catastrophic failure.[3]

Propellants

Main article: Liquid rocket propellants

Thousands of combinations of fuels and oxidizers have been tried over the years. Some of the more common and practical ones are:

- liquid oxygen (LOX, O2) and liquid hydrogen (LH2, H2) - Space Shuttle main engines, Ariane 5 main stage and the Ariane 5 ECA second stage, the first stage of the Delta IV, the upper stages of the Saturn V, Saturn IB, and Saturn I as well as Centaur rocket stage

- liquid oxygen (LOX) and kerosene or RP-1 - Saturn V, Zenit rocket, R-7 Semyorka family of Soviet boosters which includes Soyuz, Delta, Saturn I, and Saturn IB first stages, Titan I and Atlas rockets

- liquid oxygen (LOX) and alcohol (ethanol, C2H5OH) - early liquid fueled rockets, like German (WW2) A-4, aka V-2, and Redstone

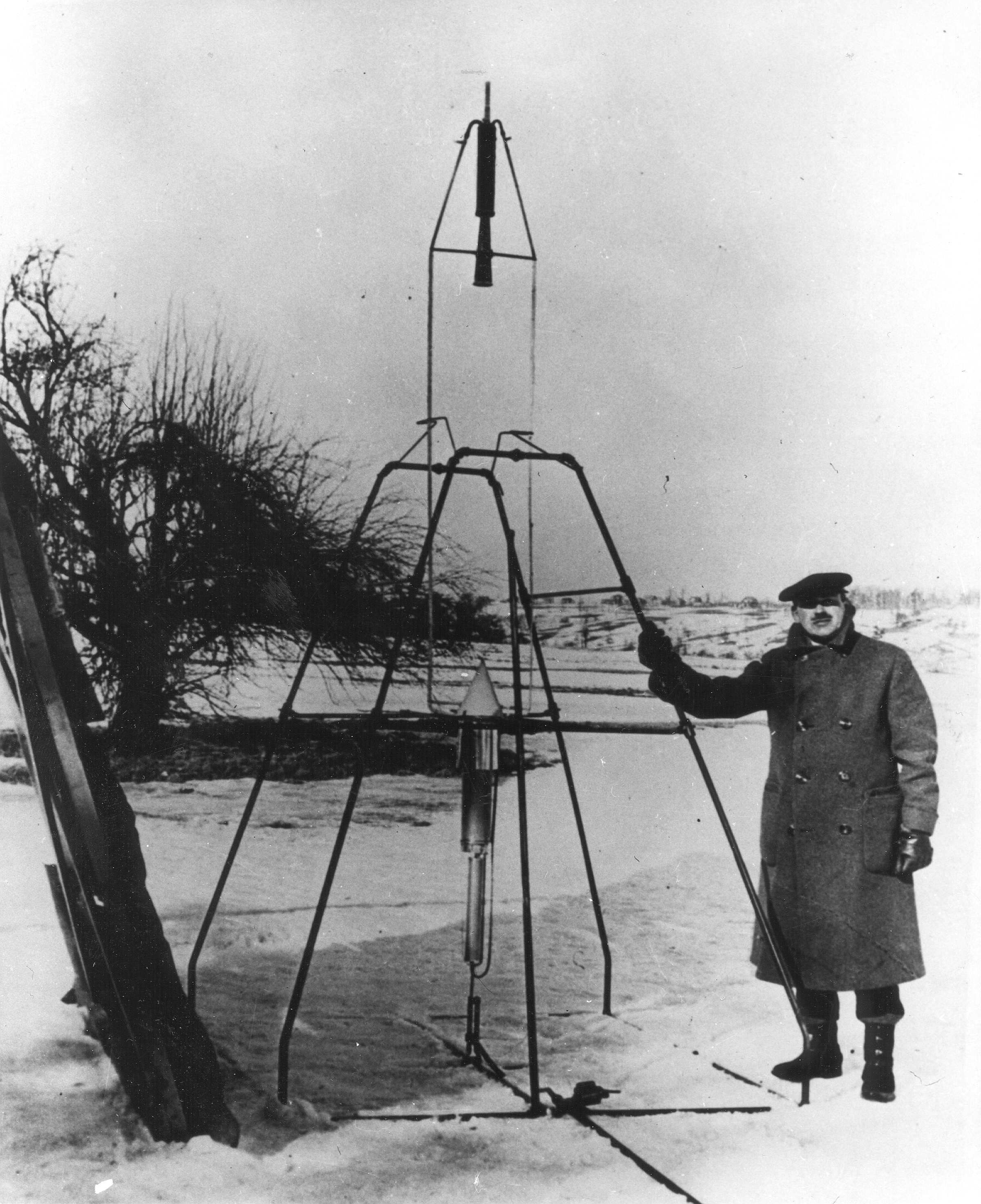

- liquid oxygen (LOX) and gasoline - Robert Goddard's first liquid-fuel rocket

- T-Stoff (80% hydrogen peroxide, H2O2 as the oxidizer) and C-Stoff (methanol, CH3OH, and hydrazine hydrate, N2H4•n(H2O as the fuel) - Walter Werke HWK 109-509 engine used on Messerschmitt Me 163B Komet a rocket fighterplane of (WW2)

- nitric acid (HNO3) and kerosene - Soviet Scud-A, aka SS-1

- inhibited red fuming nitric acid (IRFNA, HNO3 + N2O4) and unsymmetric dimethyl hydrazine (UDMH, (CH3)2N2H2) Soviet Scud-B,-C,-D, aka SS-1-c,-d,-e

- nitric acid 73% with dinitrogen tetroxide 27% (=AK27) and kerosene/gasoline mixture - various Russian (USSR) cold-war ballistic missiles, Iran: Shahab-5, North Korea: Taepodong-2

- hydrogen peroxide and kerosene - UK (1970s) Black Arrow, USA Development (or study): BA-3200

- hydrazine (N2H4) and red fuming nitric acid - Nike Ajax Antiaircraft Rocket

- Aerozine 50 and dinitrogen tetroxide - Titans 2–4, Apollo lunar module, Apollo service module, interplanatary probes (Such as Voyager 1 and Voyager 2)

- Unsymmetric dimethylhydrazine (UDMH) and dinitrogen tetroxide - Proton rocket and various Soviet rockets

- monomethylhydrazine (MMH, (CH3)HN2H2) and dinitrogen tetroxide - Space Shuttle Orbital maneuvering system (OMS) engines

One of the most efficient mixtures, oxygen and hydrogen, suffers from the extremely low temperatures required for storing hydrogen and oxygen as liquids (around 20 K or −253 °C)) and low fuel density (70 kg/m³), necessitating large and heavy tanks. The use of lightweight foam to insulate the cryogenic tanks caused problems for the Space Shuttle Columbia's STS-107 mission, as a piece broke loose, damaged its wing and caused it to break up and be destroyed on reentry.

For storable ICBMs and interplanetary spacecraft, storing cryogenic propellants over extended periods is awkward and expensive. Because of this, mixtures of hydrazine and its derivatives in combination with nitrogen oxides are generally used for such rockets. Hydrazine has its own disadvantages, being a very caustic and volatile chemical as well as being toxic. Consequently, hybrid rockets have recently been the vehicle of choice for low-budget private and academic developments in aerospace technology.

Small scale rocket engines

XCOR Aerospace, a California based company, is developing small scale rocket engines to power small airplanes for suborbital flights. They have tested various combination of propellants including nitrous oxide/propane, nitrous oxide/alcohol, LOX/alcohol, LOX/kerosene with success.

On April 12, 2008, California State University, Long Beach and industry partner Garvey Spacecraft Corporation jointly conducted a flight test of the Prospector 14 launch vehicle that featured a 1,000 lbf-thrust LOX/methane rocket engine developed by CSULB students. It is believed that this is the first such powered flight of this cryogenic propellant combination.

See also

- spacecraft propulsion

- Liquid rocket

- tripropellant rocket

- hypergolic rocket fuels

- Rocket engine nozzles

External links

References

- ↑ Hill, P & Peterson, C.(1992) Mechanics and Thermodynamics of Propulsion. New York: Addison-Wesley ISBN 0-201-14659-2

- ↑ XCOR Aerospace: EZ-Rocket FAQ

- ↑ Design of Liquid Propellant Rocket Engines- Huzel and Huang